Basic equipment:

Wiping equipment featuring:

- Air knife rigs with integrated knife-to-strip distance, tilt angle control, quick open, and edge-coating control device

- Air knife lip gap height adjustment

- Air knife positioners with integrated height, skew, and scan

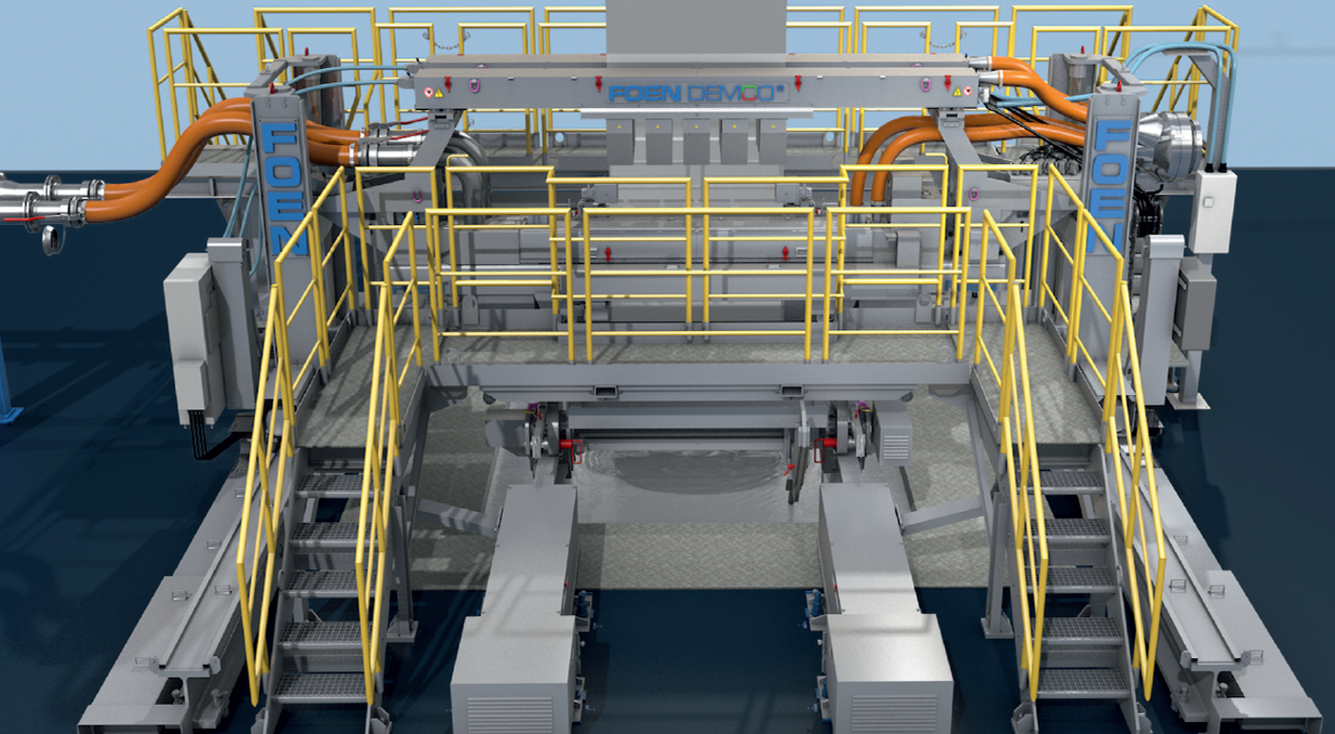

Bath roll equipment featuring:

- Sink roll rig with vertical, horizontal, and steering motions of the sink roll

- Stabilizing roll rig with horizontal motion

- Correcting roll rig with horizontal motion

- Special wear and corrosion-resistant steel for sink, stabilizing, and correcting rolls

- Ceramic sleeve system for sink, stabilizing, and correcting rolls

- Special wear-resistant material for sink, stabilizing, and correcting roll end caps

Air-wiping medium supply equipment featuring:

- Air supply system with blowers, control valves, piping, and flexible hoses with quick disconnects and pressure control

Maintenance equipment featuring:

- Maintenance and calibration stands for air knife, sink roll and correcting roll rigs that utilize a stand-alone panel for calibration

- Electrical and pneumatic maintenance control pulpit with remote control for easy calibration and setup of equipment off-line

- Electric or gas-heated bath roll preheating furnace

Automation featuring:

- HMI controls for all equipment features

- Emergency push buttons

High-performance equipment:

Air-wiping equipment featuring:

- Patented automatic air knife lip-cleaning device

- Air Knife positioners with retraction that moves the entire Air knife Unit to the front of the pot

- Newly developed air knives gap width adjustment device which allows less nitrogen to be used, reduces noise and air/nitrogen turbulence on the bath surface (creating less dross), and uses the airflow only on the actual strip width, which potentially saves up to 75% of the wiping media that would normally be wasted

- Touchless edge-coating control device

- Laser measurement for strip profile and distance-to-strip control

Bath equipment featuring:

- Specially coated sink, stabilizing, and correcting rolls

- Pneumatic or scanning (motorized) scraper to remove zinc or aluminum/zinc deposits from the sink roll

- Scanning scraper to remove deposits from the correcting and stabilizing rolls (motorized or manual)

- Dross grabber for easy removal of bottom dross from the pot

- Robot for drossing the top of the metal level

Nitrogen wiping equipment featuring:

- High temperature-resistant air knife rigs

- N2 wiping medium heating system

- Pressure control system through the blowers or separate valves

Control equipment featuring:

- Independent and stand-alone computerized automation and control package incl. HMI, PC, and Database

- Personal preinstalled data storage for automatic equipment setup

- Fully automatic integrated coating weight control moving to new parameters for the next coil based on archived data for that product

- Closed loop control interface to coating measuring gauges

- MBC Controller (feedforward mathematical coating weight model)

Special devices for galvanneal production featuring:

- Touch roll rigs with water-cooled rolls

Strip stabilizer:

The reduction of strip vibrations in the process section enables significant improvements in coating quality. Therefore, a strip correction and vibration-dampening system have been developed, which is characterized by its compact size, high force application, and very fast control times. The stabilizing effect is achieved through inductive measurement of the strip position and control of several magnetic forces across the strip width. Depending on the strip width, three or five pairs of coils are in use, whereby only the center coil is fixed and the other pairs move synchronously. In contrast to conventional hot-dip galvanizing lines where undesired strip movement occurs, this specific stabilizer eliminates the need for an over-coating target to ensure that the required minimum coating is reliably achieved over the full strip surface.

To be able to compete in a technologically fast-growing market, any continuous galvanizing line needs to be equipped with the latest technology in order to effectively increase their end product quality.

– RICC Europe GmbH, based on its long-term experience, has established a firm cooperation with the world-renowned manufacturer of air knives and stabilizers to assist you to reach your production goals. Contact Us and we guarantee that we would be an invaluable asset.